History

In the sixties two men Jan Maes and Maurice De Jonckheere met each other as colleagues in a machine company. At the end of that decade both decided to start a business in the sector of woodworking machinery and tools. The company Jan Maes specialized in the sales and logistics of renowned tooling manufacturers (e.g. AKE cutting and better). Jan Maes pioneered with the concept of service station and repair shop at that time quasi non-existent.

Maurice De Jonckheere on the other hand focused on the development and production of tooling and cutting materials. He was a true innovator.

Although operating in the same market they served both their specific customer segment.

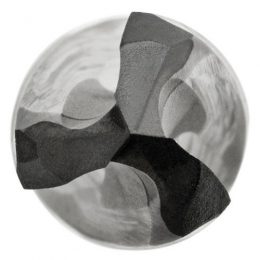

After the market development of tungsten carbide tools in the seventies and eighties they both introduced diamond tooling (PCD Polycrystalline diamond) in the early nineties.

Both companies fully engaged in this technology as early adopters.

After the expansion in the nineties followed a market consolidation in the mid nillies.

Consequently followed the merger of both companies with the name Maes Jonker.

Due to the integration of the companies further growth and development continued. Maes Jonker nowadays is well diversified internationally operating company focused on custom made solutions and short delivery time.

Because of our history the company offers a lot of advantages: customer centric, innovation, development, own production and a stable and proven organisation.

The continuous investment in the human factor and machinery makes of Maes Jonker a pro-active and ready for the future company.

Why Maes Jonker

When you consider tools and machining not only as a cost but as well as an opportunity to hedge your production.

When you approach machining and optimizing of processes holistic regarding the total cost of ownership (eg waste, scrap, downtime….)

When responsiveness and finishing quality, thanks to our organisation and the state of the art equipment matters.

When up-time and reliability are at stake

When you need competent, skilled and indiepent advise

Or simply while it is easy and comfortable to work with Maesjonker.

Your machining problems are our core business, we deliver cutting solutions

At your service….

Personalized approach

Custom made products demands individual customer treatment.

Open mind and listenging readiness

Innovation and good ideas often emerge out of the inexpected.

Versatility and involvement

Projects are acompanied by one of the owners.

Deliverables

We provide an engineering department and state of the art machine shop in order to act swiftly.

Organization

Lean, pro-active, reliable, sustainable and international network of customers and suppliers. No nonsens, hands on